Ideal solution for reduced height and weight applications

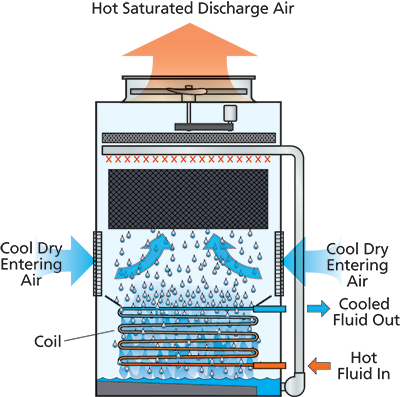

EVAPCO is proud to be the first to develop a closed circuit cooler with patented Combined Indirect and Direct Cooling technology. The ESWA closed circuit cooler design combines both PVC fill and a closed circuit coil, making this unit ideal for wet cooling applications where thermal and energy efficiency is of utmost concern and the ideal solution for strict height and weight applications. Utilizing EVAPCO's patented Sensi-Coil® Technology featuring CrossCool™ Internal Tube Enhancement, the ESWA is incredibly efficient, providing excellent cooling capabilities using reduced horsepower and a more compact box size.