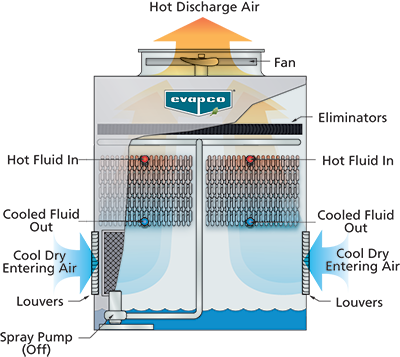

The containerized Advanced Technology closed circuit cooler provides an induced-draft, axial fan solution for a wide array of outdoor cooling capacities, and is optimally designed to fit inside a shipping container to reduce ocean freight costs. Bringing EVAPCO's Advanced Technology design to closed circuit coolers, the cATWB features the Thermal-Pak II® Coil with CrossCool™ Internal Tube Enhancement, offering incredible evaporative cooling capacity.